By Moody Mattan

•

April 13, 2025

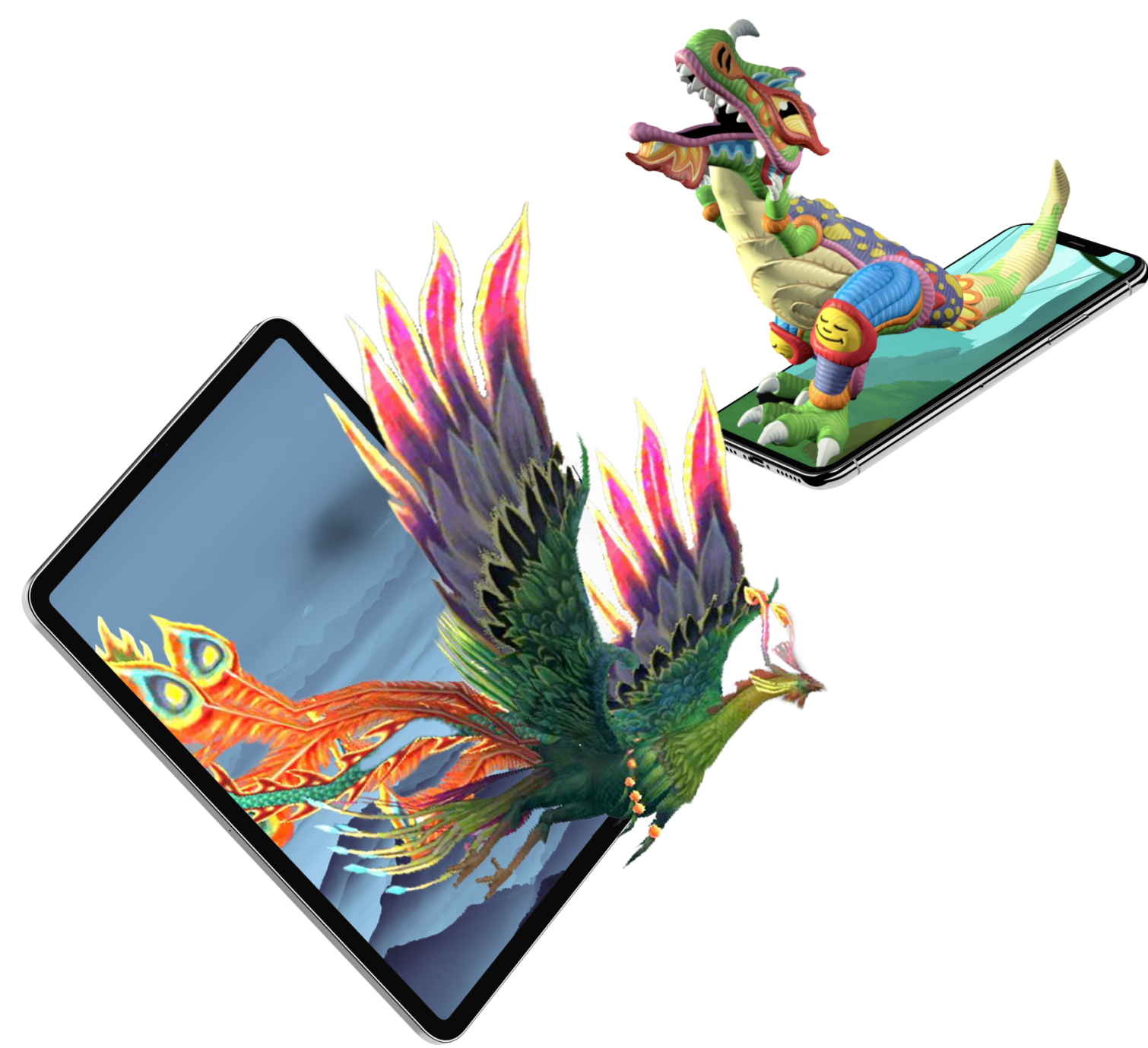

Executive Summary In an era of tightening margins and global competition, manufacturing leaders are turning to Artificial Intelligence (AI) and immersive technologies – Augmented Reality (AR) and Virtual Reality (VR) – to boost productivity, cut costs, and enhance workforce capabilities. Across the automotive, aerospace, and electronics sectors, these technologies are delivering tangible improvements in key performance indicators (KPIs). Manufacturers report reduced downtime (sometimes by as much as 50%), increased throughput and quality, expedited training, and significant cost savings due to AI-driven optimization and AR/VR-enabled process improvements. Major companies such as Toyota, Boeing, Lockheed Martin, Bosch, Siemens, and Samsung are investing heavily in AI for predictive maintenance and supply chain optimization, deploying AR/VR on factory floors for training and assembly guidance . The AR and VR solutions in manufacturing represented a roughly $8 billion market in 2022 and are projected to grow at approximately 28% annually this decade, highlighting their increasing significance. This executive report details how automotive, aerospace, and electronics manufacturers leverage AI, AR, and VR through case studies and data, and offers recommendations for leaders to capitalize on these technologies. Key highlights include: Automotive: AI-based predictive maintenance and quality control (e.g., Toyota, BMW) are reducing unplanned downtime and defects, while AR and VR are streamlining complex assembly tasks and accelerating worker training at companies like Volkswagen and BMW. Aerospace: AR is enabling more efficient assembly of high-complexity products (Boeing’s wiring harnesses, Lockheed Martin’s spacecraft) with zero errors and faster completion. VR is used for design simulations and immersive training at Boeing, reducing the need for costly physical prototypes. Electronics: AI-driven analytics (Bosch, Samsung) improve production yield and energy efficiency – Bosch’s AI system cut energy use by 18% at one plant – while AR/VR support complex manufacturing and maintenance tasks (Siemens’ VR training cut training time by 66%). Each section below deeply explores these use cases, providing data points, quotes from industry leaders, and visual charts to illustrate the impact on manufacturing efficiency. An executive-level conclusion offers recommendations for adopting these technologies to achieve similar gains.